Hot keywords:

Pressed candies, as a convenient functional food, have attracted much attention in the health food market in recent years due to their easy portability, diverse flavors, and strong customization. For brand owners, collaborating with source manufacturers through OEM/ODM mode can quickly achieve the transformation of products from research and development to market launch.

Ⅰ、 The main modes of compressed candy processing

1. Incoming processing mode

The customer provides the raw materials themselves (which must meet food grade standards), and the OEM factory is responsible for tablet pressing, packaging, and quality inspection. This mode is suitable for brands with mature formulas, which can reduce the cost of raw material procurement, but it is necessary to ensure that the raw material qualifications are complete and meet production requirements.

2. OEM/ODM customization mode

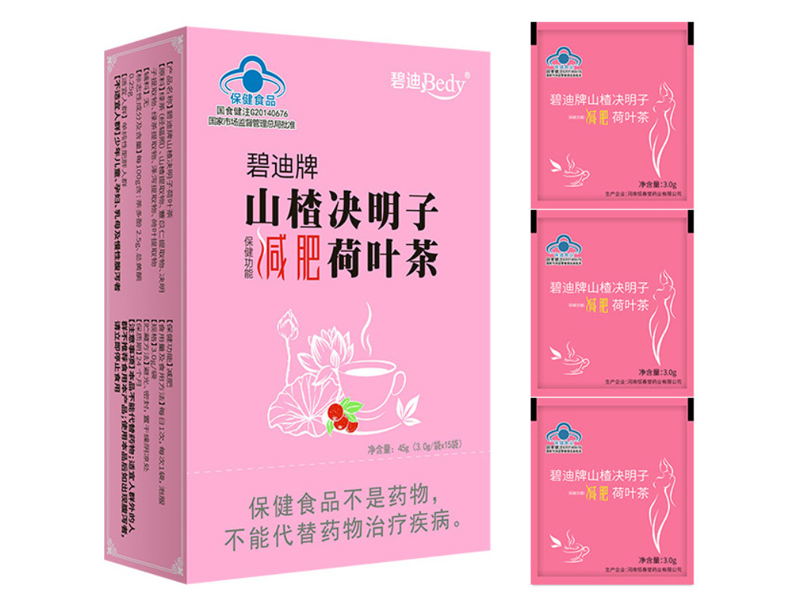

The OEM provides full process services from formula research and development, raw material procurement to packaging design. The brand only needs to provide the brand logo and market demand direction, which is suitable for startups lacking technical resources. For example, Henan Hengchuntang Pharmaceutical Co., Ltd. can customize tablet shapes (round, irregular), coating processes (to improve taste), and differentiated packaging for customers.

3. Finished product OEM model

Directly select the existing formula products from the OEM factory and label them with our own brand. This model has a short cycle, but there is a high risk of product homogenization.

Ⅱ、 Analysis of the entire process of compressed candy processing

1. Pre preparation stage

-Qualification review: The OEM factory needs to have an SC food production license, with a production scope covering "pressed candies", and pass GMP or HACCP certification. For example, Henan Hengchuntang Pharmaceutical Co., Ltd. has a GMP 100000 level purification workshop and SC qualification, and can produce various dosage forms such as tablets and capsules.

-Requirement communication: Clarify product positioning (such as food grade and health grade), tablet weight (0.15-4 grams/tablet), packaging form (aluminum foil bag, blister board), and functional requirements (such as supplementing nutrition and regulating intestines).

2. Research and development and sampling

-The OEM factory designs formulas based on customer needs and produces samples through processes such as granulation, drying, and tablet pressing. The key parameters include particle moisture content (≤ 0.5%), tablet pressure (controlling hardness), and disintegration time limit.

-The sample needs to undergo microbiological and heavy metal residue testing, and enter the mass production stage after the customer confirms the taste and appearance.

3. Production implementation stage

-Raw material processing: Raw materials need to be crushed, sterilized, and mixed to ensure uniformity.

-Granulation and compression: high-speed rotary granulation mechanism is used for granulation; When pressing, it is necessary to control the environmental humidity (≤ 60%) to prevent sticking to the mold.

-Coating and packaging: Some products require coating to improve taste or control release speed; The inner packaging (such as aluminum foil sealing) and outer packaging (boxed) must comply with food grade material standards.

4. Quality inspection and delivery

-Finished products need to be randomly inspected, including hardness, disintegration time limit, microbial indicators, etc.

-The OEM provides factory inspection reports and supports third-party testing and verification.

Ⅲ、 Cooperation precautions

1. Qualifications and Compliance

-The raw materials must comply with the "Catalogue of Medicinal and Food Sources" and the "Standards for the Use of Food Additives", and the use of non edible substances is prohibited.

-The packaging design needs to undergo legal review to ensure that the labels indicate the product type, net content, and warning language.

2. Cost and Minimum Order Quantity

-The minimum order quantity is usually set by the OEM based on the basic cost, and may be charged according to the minimum order quantity when the order quantity is insufficient. There is also a minimum purchase quantity requirement for packaging materials, such as aluminum foil bags.

3. Risk prevention and control

-Advance planning for SC code application and health food registration.

Ⅳ、 Source Manufacturer - Henan Hengchuntang Pharmaceutical Co., Ltd. Processing Advantage

1. Complete qualifications: With SC certification, GMP workshop and health food production license, it can produce various dosage forms such as tablets, capsules, tea preparations, etc.

2. Technical strength: Equipped with modern extraction and testing equipment, supporting the crushing, sterilization, and formula optimization of medicinal and edible raw materials.

3. Full process service: Provide one-stop solutions for formula research and development, packaging design, approval declaration, and logistics distribution.

The core of tablet candy processing lies in selecting compliant and efficient source manufacturers for tablet candy processing, and achieving rapid product implementation through clear process division of labor. Whether it is material processing or OEM customization, the brand needs to focus on qualification review, raw material compliance, and production transparency. Cooperating with strong enterprises such as Henan Hengchuntang Pharmaceutical Co., Ltd. can effectively reduce market risks and enhance product competitiveness.

Consultation

0086 15516170982TEl